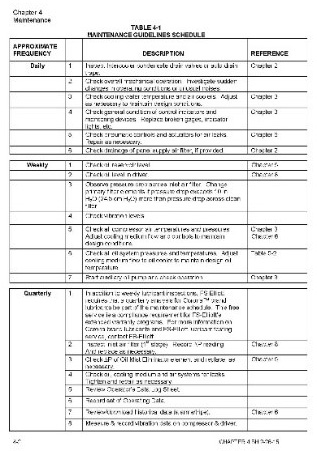

Follow the original technical manual-Chapter 4-Maintenance chapter

Regular inspection service

Annual or regular maintenance

Annual overhaul and maintenance

- Disassembly, cleaning and derusting of the diffuser volute of the first, second and third stage. The volute and the back plate diffuse the air flow path and are sprayed with high temperature and rust-resistant spray paint to prevent rust.

- The first stage of the inlet piping, expansion joints and inlet IGV control valve disassembly, cleaning, painting and rust prevention.

- Pipe clamp sealing Gasket 8 ", 6 ", 5 "and 4" , disassembly and assembly inspection.

- Disassembly and assembly of the second stage of the air inlet pipe, cleaning, painting the inner wall of the pipe to prevent rust and cleaning the flange surface.

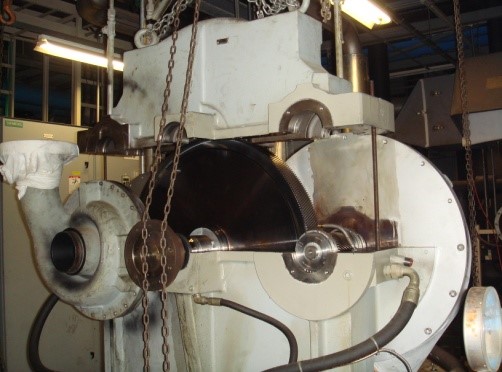

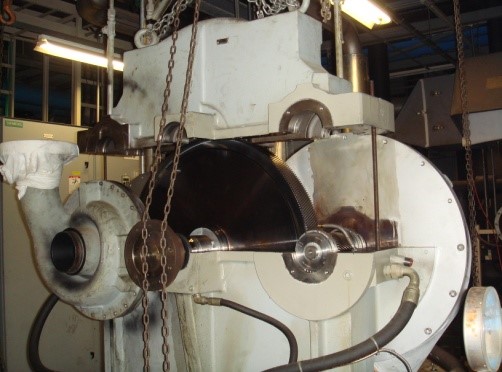

- Lifting, cleaning and assembling the upper cover of the gear box. Seal O-Ring replacement. All screws are cleaned.

- There are four sets of high-speed and low-speed thrust bearings, which are disassembled and cleaned.

- There are three groups of seal assemblys in high speed section and low speed section, which can be disassembled and cleaned. O-Ring replacement.

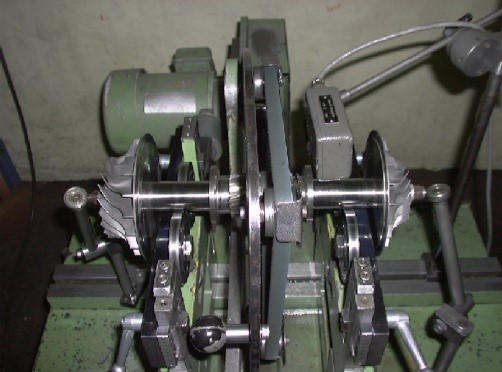

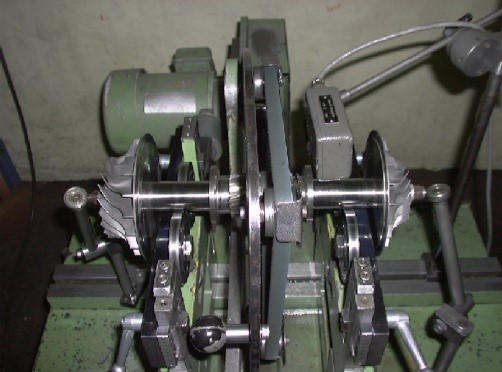

- There are two sets of high-speed and low-speed moving impeller rotor assemblys, which can be disassembled, cleaned, and dynamic balance correction (with dynamic balance correction certificate attached).

- Disassemble and inspect the bullgear bearing. Clean or replace the Oil Seal of the spindle oil seal.

- Measurement and adjustment of the first, second, and third-stage impeller clearance and bullgear bearing clearance.

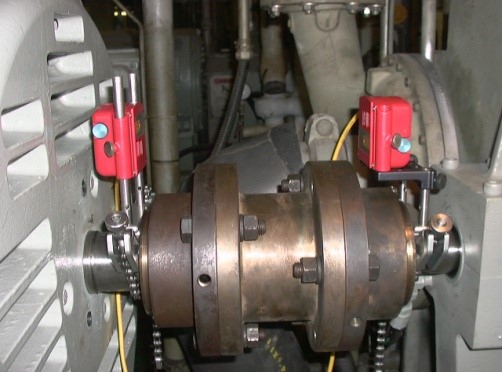

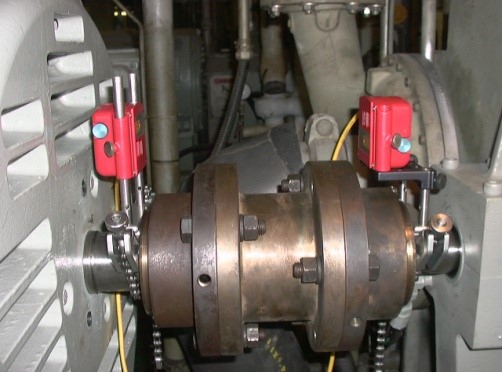

- Disassembly, assembly and cleaning of non-contact vibration probes, adjustment and setting of gap voltage.

- Disassembly, assembly and cleaning of air seal system pipelines, adjustment and setting of seal air pressure.

- Air seal pressure regulating valve and pressure relief valve are disassembled and inspected.

- Motor laser alignment correction, coupling disassembly and assembly, cleaning, spraying temperature-resistant paint to prevent rust and inspection.

- Detection and adjustment of the deformation of the first, second and third sections of the backplane.

- Action test and adjustment of intake control valve and unloading control valve.

- The exterior of the compressor body is cleaned, rust removed, and painted to prevent rust.

- Try it out.